In life, as in jewellery making, there are things that you can’t always learn from books or from taking a class; practical things like how to remove a broken drill bit stuck in a piece of metal, shortcuts to help you work more efficiently, time-saving tips, and tricks of the trade. These are things you learn from other people; people who have a lot of experience in the trade, people in the trenches. Of course, you could also find out these things eventually through trial and error – well, error, mostly.

Something I wish I could ask all the goldsmiths out there is: What are your favorite tools or pieces of equipment and why? There is a lot to be learned that way, and not just in relationship to their work, but about new and better ways of using these tools as well.

This is the first of a series of posts where I’ll be sharing my favourite tools and tips with you, and I look forward to hearing from all of you as well. What are your favourite tools, and what “life-saving” tips do you know that you could share?

High on my list of the must-have tools in the studio is masking tape. I have several rolls in different parts of my studio placed in strategic places. There is a roll on my bench, always within easy reach. Masking tape has gotten me out of several tricky “sticky” situations and has saved me a lot of time and frustration.

Something masking tape is good for, of course, is … masking.

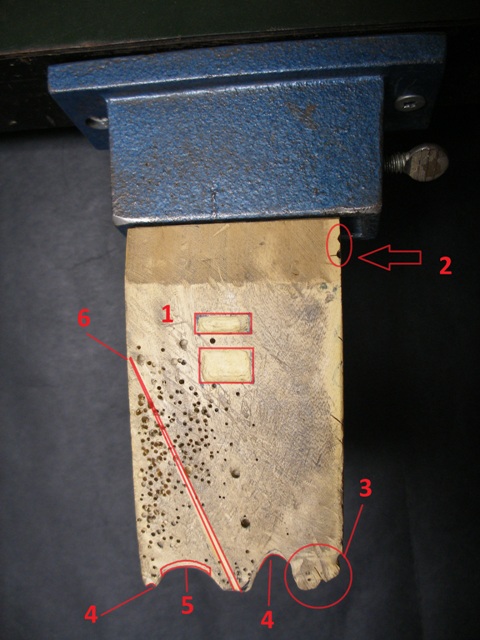

In preparation for etching, cover the parts of your design that you want to “keep”; masking tape acts as “resist” and protects the metal from being eaten away by the chemicals. This works well when etching copper or brass with ferric chloride.

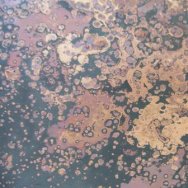

On the finished piece, the areas that were covered with masking tape are smooth and slightly raised; all the recessed areas of the design have been etched. They show a beautiful texture, especially around the edges of the masked parts.

Pieces of tape can be torn by hand or specific shapes can be cut out with scissors. You can see here how this produces different results. With torn pieces of tape, there is a more pronounced texture (“pull lines”) around the edges, whereas with the cut pieces, the etch is cleaner and sharper around the shapes.

The same masking technique can be used for sandblasting as well. After finishing and polishing your piece, cover the parts of your design that need to remain smooth and polished. Whatever is left exposed will have a lightly textured and matte surface after sandblasting. For heavy sandblasting, duct tape or electrical tape might be more suitable, but I find that masking tape is sufficient for standard results.

It’s great for covering or protecting various surfaces.

Since rivets are put in and set after a piece has been finished and polished, it helps to protect the area around the rivets to prevent damaging the surface of the metal when tapping them in with the riveting hammer.

No matter how careful you are when setting a stone, accidents happen! To be safe and to protect your newly finished piece from scratches, cover with masking tape.

Cover a stone that’s already set, if you need to do some more cleaning around the setting.

You can use it to tape together a stack of sheets of metal.

This is useful when you need to drill through several sheets and make sure all the holes are perfectly lined up (for riveting for example).

Masking tape is quite sticky and can be used to make “handles”.

Use them to hold things that are very small, difficult to hold or slippery (like stones). With a “handle” it’s easier to put a stone in a setting, and take it out, to check whether it fits or it is level.

To drill pearls. A pearl drilling vise is not really practical, because the pearl tends to slip out and worse, the tool can damage the delicate surface of the pearl.

Life-saver. A piece of masking tape can be used to pull a stone out of a tight setting (works most of the time – more tips later on what to do when the stone is really stuck).

Finally…

Some people prefer duct tape. Yes, it is tougher and stickier, but I find that it tends to leave behind too much of a sticky residue once removed. Other people swear by green tape or painter’s tape. I find it not quite sticky enough and sometimes too flimsy.

To each her own.

Oh, and one more thing!

When a bandage is not available, guess what I reach for?

Note: The idea for this blog post comes from Secret Shop Weapons, a book recently published by MJSA Press.